Portfolio & Case Studies

Real projects, real results. Here's how we've helped companies turn their ideas into successful products.

Custom Industrial Part

Automotive industry client needed high-strength parts. Challenge: Replace expensive machined components. Solution: We produced custom 3D printed parts with ±0.1mm precision tolerance. Results: 60% cost reduction, delivery 3 weeks faster, and 100% functional compatibility with original parts.

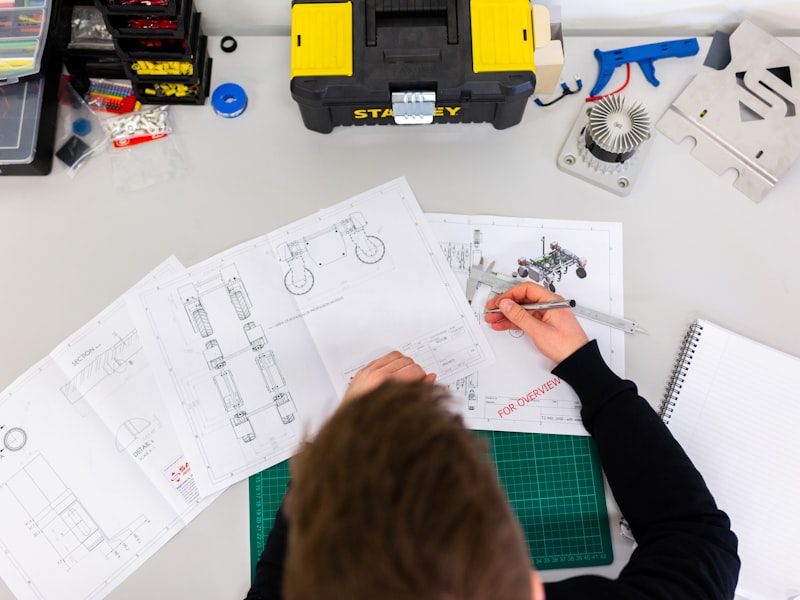

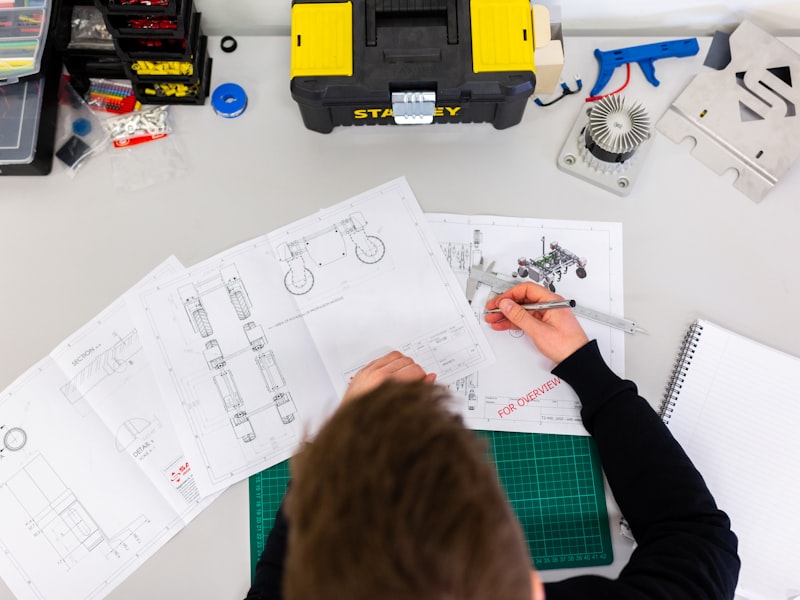

Rapid Prototype Development

Tech startup needed to develop a product concept quickly. Challenge: Create multiple iterations fast enough for an investor pitch. Solution: We delivered multiple prototype iterations in just 1 week. Results: Client secured funding, cut 3 months off development time, and saved $25,000 in tooling costs.

Custom Design Object

Architectural project required a unique decorative element. Challenge: Complex geometry that traditional manufacturing couldn't handle. Solution: Multi-material 3D printing with specialized finishes. Results: Stunning visual impact, 40% cost savings compared to traditional methods, and completion 2 months ahead of schedule.

Bulk Production Series

Consumer product company needed large-scale production for a product launch. Challenge: Produce 10,000 units within 4 weeks. Solution: We optimized our production workflow using multiple printers running simultaneously. Results: Delivered exactly on time, achieved 55% cost savings compared to injection molding, and maintained zero defects throughout the entire run.